What Is a Drive Belt and How Does It Work?

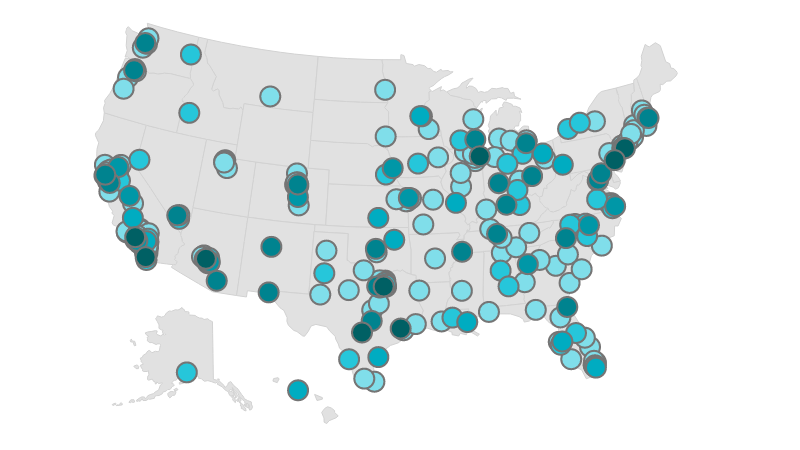

A drive belt is a relatively long, flat, multi-ribbed belt driven by the engine’s crankshaft pulley. It powers many, often all, of the engine accessories such as the alternator, air conditioning compressor, power steering pump, water pump, and air pump. The drive belt is tensioned by a hydraulic or spring-loaded automatic tensioner. Some older vehicles use a drive belt for most accessories but also have a shorter v-style belt to drive specific components like the power steering pump. At Nationwide Mechanics, we connect you with experienced mobile mechanics who provide convenient drive belt inspection and replacement services wherever you are.

Drive Belt Replacement Cost

The cost of a drive belt varies widely depending on your vehicle’s make and model. On average, the belt alone costs between $25 and $75, with luxury or performance vehicles potentially costing more. It is crucial to choose a quality replacement belt to ensure long-term vehicle health. Labor costs vary by location and vehicle complexity. Overall, a drive belt replacement with Nationwide Mechanics typically ranges between $150 and $300, saving you 20-30% compared to traditional dealers, plus we come to you!

When to Replace the Drive Belt

- Scheduled Maintenance: Belt manufacturers generally recommend replacement around 90,000 miles, but regular inspections should be conducted beforehand.

- Noises or Visible Damage: Squealing sounds, belt slippage, or visible signs of wear like cracks, missing chunks, or shredding indicate a replacement is needed. Sometimes a loose belt can cause these issues but an inspection is essential.

- Battery Warning Light: A loose or failing tensioner may cause the alternator to underperform, discharging the battery and triggering the warning light.

- Engine Overheating: Since the drive belt often powers the water pump, belt failure or poor tension can cause rapid overheating.

How Our Mechanics Replace the Drive Belt

Before removal, the mechanic checks the idler pulley and tensioner for noise or wear and ensures all pulleys align properly. The belt routing is noted, then the tensioner is released to free the belt. The mechanic removes the old belt and inspects rotating components for smooth operation. A new belt is installed while holding the tensioner, then released to apply proper tension. Finally, the engine is run to confirm normal operation.

Is It Safe to Drive with a Drive Belt Problem?

No. Driving with a damaged or failing drive belt risks sudden breakdowns. Belt failure can stop alternator charging, draining the battery and disabling vehicle electronics. If the belt drives the water pump, failure causes immediate engine overheating, risking severe engine damage.

Additional Considerations When Replacing the Drive Belt

Typical service life is about 90,000 miles, but premature failure warrants inspection for pulley misalignment, crankshaft balancer issues, binding pulleys, or defective tensioners. Proper belt routing is critical to function and tension. When uncertain about belt-related noises, mechanics may run the engine briefly without the belt to isolate sounds. Checking all belts regularly helps catch issues early.